News

-

Dabang Fastener at 15TH FASTENER EXPOSHANGHAI

From June 17 to 19, 2025, the 15TH FASTENER EXPOSHANGHAI was held at the National Exhibition and Convention Center. As one of the important exhibitors in the industry, Dabang Fasteners brought a number of innovative products and technical solutions to the exhibition, demonstrating its R&D str...Read more -

Why is retapping necessary for hot-dip galvanized nuts?

Why is retapping necessary for hot-dip galvanized nuts? Advantages: 1. Because the hot-dip galvanized zinc layer is thicker, when it is matched with hot-dip galvanized bolts, there is a certain probability that it cannot be screwed in. If the back-tapping process is adopted, the zinc layer of the...Read more -

The difference between structural bolts and non-structural bolts

The core difference between structural bolts and non-structural bolts lies in the mechanical role they play. Structural bolts are directly involved in the force transmission of buildings or mechanical systems, such as steel structure beam-column connections, bridge nodes and other key parts. Such...Read more -

What are steel structure bolts

Steel structure bolts are key load-bearing connectors in steel skeleton systems such as buildings and bridges, and are mainly used to bear dynamic loads and shear stresses. Different from ordinary bolts, their strength grades are generally above grade 8.8. The tensile strength of M24 grade 10.9 h...Read more -

What is a wave washer?

DIN 137 wave washers play a key role in pressure compensation and anti-loosening and shock absorption in mechanical connections. Its unique wave-shaped structure effectively compensates for the attenuation of preload caused by temperature changes or vibrations by forming elastic deformation in th...Read more -

DIN444 eye bolts and DIN580 Lifting Eye Bolt

DIN444 eye bolts and DIN580 Lifting Eye Bolt are two types of key connectors under German industrial standards, and they play completely different functional roles in mechanical design and engineering assembly. The core feature of DIN444 eye bolts is their articulated head design, which allows ±3...Read more -

Electroplated galvanized bolts vs color plated zinc bolts

Although electrogalvanized bolts and color-coated zinc bolts seem to be similar in appearance, there are obvious differences in their anti-corrosion performance and application scenarios. The electro galvanizing process forms a silver-white zinc layer on the surface of the bolt through electrolyt...Read more -

Manufacturing process of rivet nuts

As an important fastening element in modern industry, the manufacturing process of rivet nuts integrates a number of precision process technologies. This special fastener with internal threads is widely used in automobile manufacturing, electronic equipment, rail transportation and other fields, ...Read more -

What you need to know about Cage nut

As a key component in the field of mechanical connection, Cage nut play an irreplaceable role in preventing thread loosening. Unlike ordinary nuts that rely on simple friction to maintain tightening, Cage nuts achieve a dual anti-loosening mechanism through special structural design. From automob...Read more -

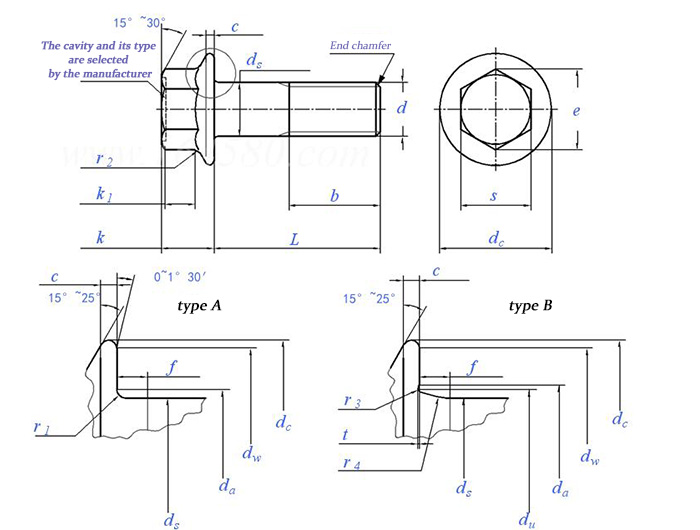

Flange bolts and flange nuts

Flange bolts and flange nuts are key components in the connection of pipeline systems and pressure vessels. Their structural features are reflected in the integrated flange surface at the bolt head or the bottom of the nut. This integrated design combines the functions of traditional bolts and fl...Read more -

How to choose the right bolts in construction projects

In various construction projects, bolt selection requires systematic consideration of multiple factors such as structural characteristics, load characteristics and environmental conditions. First, the type of bolt needs to be determined according to the functional requirements of the connection p...Read more -

Washers: Reliable guarantee for mechanical connection

In the modern industrial system, the cooperation between bolts and nuts is the basis of mechanical connection, and washers, as the key components between the two, directly determine the reliability and durability of the connection. Despite its small size, washers can effectively cope with complex...Read more -

Screws and bolts – the twin stars of the fastening world

Both screws and bolts are common fasteners, but they have some differences in shape, use, structure and connection method. Here is a comparison between the two: 1. Shape and structure Screw Threaded part: The thread of the screw is usually full thread, that is, it is threaded from the head to t...Read more -

The Mystery of U-Bolt Shapes

U-bolts, named after their shape resembling the letter “U”, are one of the most recognizable fasteners in the engineering field. Unlike butterfly bolts, which emphasize freehand operation, and unlike hex bolts, which pursue torque transmission, U-bolts are widely used in pipeline fixi...Read more -

US Bolts VS Metric Bolts

Fundamental differences in standard systems 1. Measurement basis American bolts (UNF/UNC) are based on imperial units (inches), while metric bolts (such as ISO 7380) are based on millimeters. For example, 1/4-20 UNC (American) represents a coarse thread with a diameter of 1/4 inch and 20 threads ...Read more